🍊 orange update 🍊

Update on the air quality testing with the miner running in the sound proofed unit. I used an electronic Air Quality testing device to do this.

In summary, after an hour of running the miner, it actually improved the air quality by a small margin. This is good, no nasty stuff coming out when the miner is running. Also, it increased the room temperature from 21.6 to 24.9 degrees Celsius after 1 hour of running (standard size living room with furniture).

Things done to control the testing environment.

1) Closed windows and doors so there is none or very little airflow coming into the testing room.

2) Let the testing device run for an hour in the room to get an accurate starting reading.

3) Placed the testing device around 1.5 meters away from the warm air vent. Above the unit and to the side of it where it would get some of warmer airflow.

4) No movement of anything in the room.

After 1 hour of letting the testing device settle in the room, I took 3 readings 2 minutes apart to get an accurate starting reading. (This is before the miner is switched on)

PM2.5 = 4.4, 4.1, 4.2 (Average = 4.233)

PM10 = 7.8, 6.8, 6.0 (Average = 6.867)

HCHO = 0.02, 0.02, 0.01 (Average = 0.0167)

TVOC = 0.02, 0.02, 0.02 (Average = 0.0200)

Temperature Degrees Celsius = 21.6, 21.6, 21.6 (Average = 21.60)

After switching the miner on, I took 3 readings every 20 minutes (20min, 40mins and then at 60mins).

PM2.5 = 3.4, 3.1, 3.2 (Average = 3.233)

PM10 = 5.8, 5.2, 5.6 (Average = 5.533)

HCHO = 0.01, 0.02, 0.01 (Average = 0.0133)

TVOC = 0.01, 0.02, 0.02 (Average = 0.0167)

Temperature Degrees Celsius = 22.9, 24.1, 24.9 (Average = 23.97)

I will do some more extended testing when the weather gets cooler.

#DIY #Bitcoin #Mining #BTC #Airquality

🍊 orange update 🍊

After many hours of learning about wood finishes I found a product and technique that seems to work and one that is relatively safe and idiot proof.

https://image.nostr.build/e138b4cdb112d73a8e75ca126794875a65817727bee2e8706b35de9369c903ae.png

I used some sand paper and gently sanded down this block of wood in one direction (along the wood grain).

I did a couple minutes with different sand paper grit levels 60,100,120,150. Between each level I vacuumed it, wiped it with a cloth and used some pressurised gas to remove any dust. When I get round to doing the table top I will also use 80 grit sand paper since I did not have it available right now.

https://image.nostr.build/0769173ca0513005bf3c220d5b079af7d39a4b97ee2d511e4824fd9d6e5d71ff.png

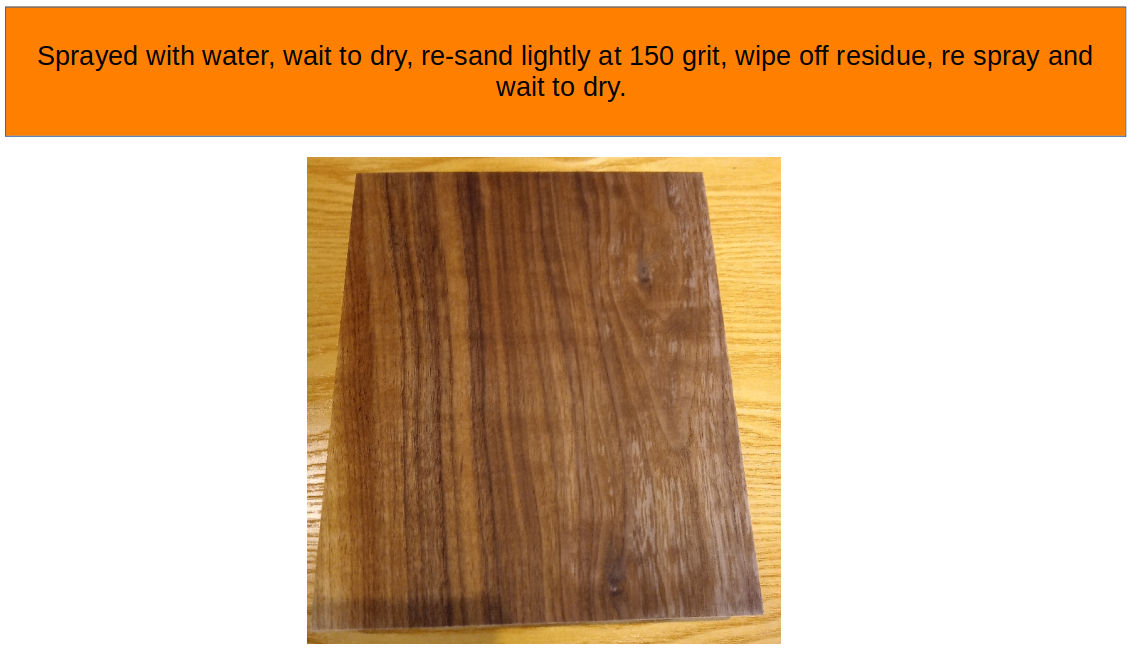

After removing all the dust with a cloth, vacuum and pressurised gas, I then evenly sprayed the wood with water and wiped it down. I let the wood dry then sanded it very gently by hand with 150 grit sand paper. Followed the same procedure as before to remove any dust. Sprayed with water again, let the wood dry. I did it twice because it felt a little off after the first round.

https://image.nostr.build/caa7973edc29d38a512a8a15df8ff9cb6e543f2e578f1b478d4f66cd58386b47.png

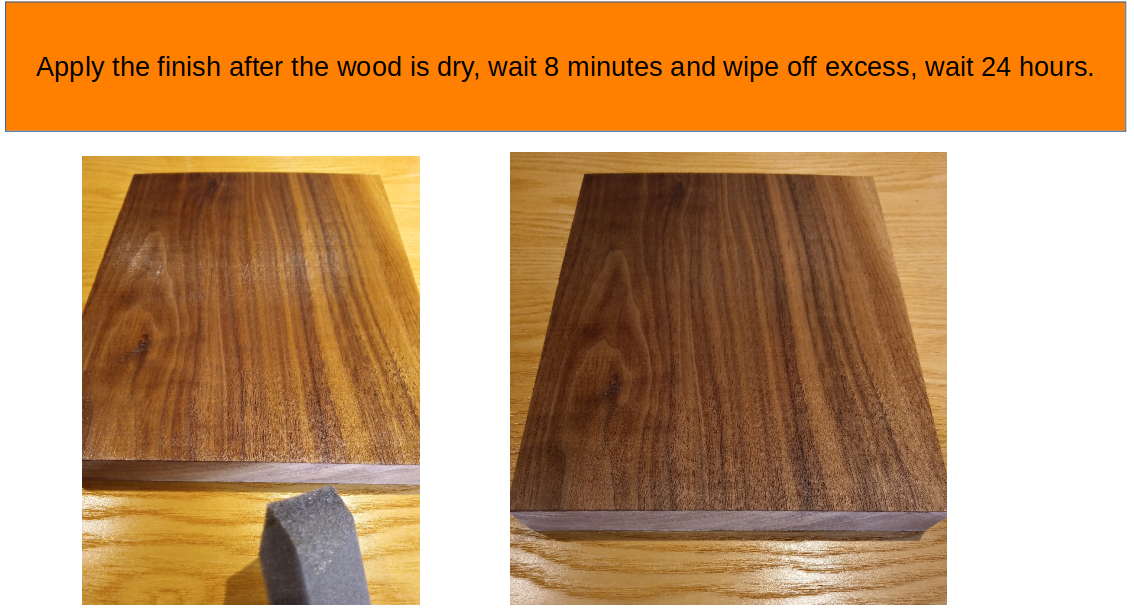

Soon after the water dried, I applied an almost clear finish to the wood (Rubio Monocoat) with a foam brush, let that settle in for around 8 minutes, then wiped off any excess liquid with a soft pad. I then waited 24hrs for the next part.

https://image.nostr.build/107212f77ef59ab097f333682631de87595ba42a035903dc04ce34a57d199b18.png

After waiting, I used 320 grit sandpaper and gently sanded down the wood, used a vacuum, cloth and pressurised gas to remove any dust. Then I applied the second coat of the finish, waited 8 minutes and wiped off the excess.

It should take around 1 week to fully cure, at that point I will do some durability testing on it.

Some notable YouTube channels that helped with this finish method was "Lincoln St. Woodworks" and "Bent's Woodworking".

#DIY #Bitcoin #Mining #BTC #Wood #Woodworking #Hardwood #Finish

Showing page 1 of

15 pages